Pam Mae Brwsh Carbon o Ansawdd Uchel ar gyfer Modur DC yn Hanfodol ar gyfer Perfformiad Dibynadwy?

2025-11-21

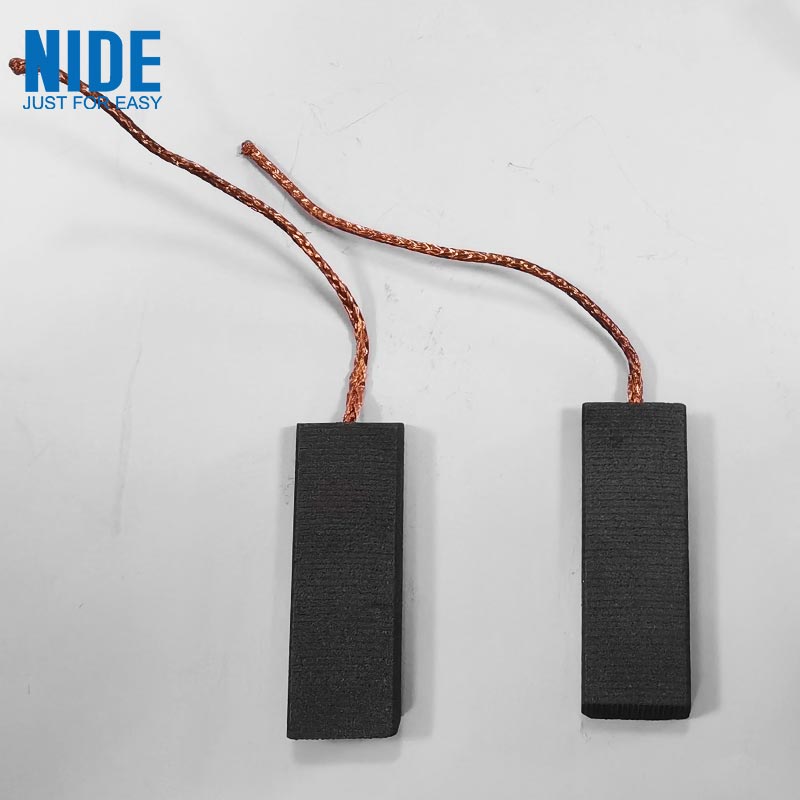

When discussing the stability, lifespan, and efficiency of a DC motor, few components matter as much as the Carbon Brush for DC Motor. This small yet crucial part enables smooth electrical contact, consistent power delivery, and long-term mechanical reliability. In many industries—automotive, home appliances, power tools, industrial machines, and generators—the choice of carbon brush directly affects operational performance. Companies like Ningbo Haishu Nide International Co., Ltd. specialize in offering durable, precise, and customizable carbon brush solutions that meet a wide range of motor requirements.

This article explores why carbon brushes are important, how they work, what parameters matter most, and how choosing the right product can improve overall performance.

What Makes the Carbon Brush for DC Motor Function Effectively?

A Carbon Brush for DC Motor operates by conducting current between stationary wires and the rotating armature. Its effectiveness depends on several factors:

-

Material composition (electro-graphite, resin-bonded, metal-graphite)

-

Hardness and density

-

Spring pressure and brush shape

-

Current load capacity

-

Wear resistance and friction characteristics

These factors determine how stable the electrical contact is, how fast the brush wears, and how well the motor performs under different loads. A well-designed brush minimizes sparking, reduces heat, and ensures smooth rotation.

How Do We Determine the Key Parameters of a Carbon Brush for DC Motor?

To ensure compatibility with your DC motor, it's essential to understand the basic technical parameters. Below is a simplified table of common specifications offered by Ningbo Haishu Nide International Co., Ltd..

Product Parameters of Carbon Brush for DC Motor

| Parameter Category | Specification Details |

|---|---|

| Material Options | Electro-graphite, Resin-bonded, Metal-graphite |

| Dimension Range | Custom sizes from 4×6 mm to 20×32 mm |

| Hardness | HB 35–85 depending on material |

| Resistivity | 8–14 µΩ·m |

| Rated Voltage | 6V–240V DC motor applications |

| Application Types | Automotive motors, power tools, home appliances, industrial motors, generators |

| Accessory Options | Springs, holders, shunts, terminals |

These parameters ensure the Carbon Brush for DC Motor meets your precise operating conditions, whether high-load industrial machinery or compact home appliances.

Why Does Choosing the Right Carbon Brush for DC Motor Matter?

Selecting the proper carbon brush directly affects performance in several ways:

1. Improved Motor Efficiency

A compatible brush reduces friction and maintains stable electrical conductivity, improving power transfer.

2. Extended Motor Lifespan

High-quality materials minimize wear and reduce commutator damage, leading to longer service life.

3. Lower Maintenance Costs

Durable brushes require fewer replacements and reduce downtime in industrial settings.

4. Reduced Noise and Sparking

Precision-manufactured brushes ensure smooth operation with minimal vibration.

When you source from reliable suppliers such as Ningbo Haishu Nide International Co., Ltd., you receive products engineered for stability, durability, and consistent performance.

What Applications Commonly Use Carbon Brush for DC Motor?

Carbon brushes are widely used across industries because of their versatility and efficiency. Key sectors include:

-

Automotive: wiper motors, starter motors, fuel pumps

-

Household Appliances: vacuum cleaners, mixers, washing machines

-

Power Tools: drills, grinders, saws

-

Industrial Equipment: conveyor systems, pumps, compressors

-

Generators and Alternators

These applications require stable contact under various speeds and torque conditions, making brush quality crucial.

How to Maximize the Performance of Your Carbon Brush for DC Motor?

Here are practical recommendations for achieving optimal performance:

✔ Ensure Proper Brush Grade Selection

Choose the correct carbon material based on load, voltage, and speed.

✔ Maintain Correct Brush Pressure

Incorrect spring force increases wear or causes unstable contact.

✔ Monitor Commutator Wear

Smooth surfaces reduce resistance and sparking.

✔ Replace Brushes in Pairs

This keeps electrical balance and prevents uneven wear.

What Features Distinguish Our Carbon Brush for DC Motor Products?

Products supplied by Ningbo Haishu Nide International Co., Ltd. include several advantages:

-

High electrical conductivity

-

Stable contact under high current

-

Smooth startup and low noise

-

Long-lasting graphite formulations

-

Customizable dimensions and terminals

-

Strict quality control and testing

These features make the Carbon Brush for DC Motor a reliable choice for both OEM and aftermarket use.

Why Is Material Selection So Important for a Carbon Brush for DC Motor?

Material grade determines brush characteristics such as friction, conductivity, temperature tolerance, and lifespan. For example:

-

Electro-graphite is ideal for high-speed motors and power tools.

-

Metal-graphite suits low-voltage and high-current applications.

-

Resin-bonded brushes work well in low-noise home appliances.

Choosing the correct grade enhances efficiency and protects the motor.

FAQ About Carbon Brush for DC Motor

1. What factors determine the lifespan of a Carbon Brush for DC Motor?

The lifespan is influenced by load, voltage, brush grade, commutator condition, and operating environment. Dust, vibration, and high temperatures can accelerate wear.

2. How do I know when to replace a Carbon Brush for DC Motor?

When the brush length is worn down to the minimum safety limit, you may notice reduced torque, increased noise, or intermittent power. Regular inspection is recommended.

3. Can different carbon brush materials be used in the same DC motor?

It is not recommended. Using mixed materials can cause uneven contact and lead to rapid commutator wear. Always use matched pairs from the same supplier.

4. Why should I choose a customized Carbon Brush for DC Motor?

Customized brushes ensure proper fit, consistent current flow, and optimized performance for specific motors, especially in specialized or high-load applications.

How to Contact Us for More Information?

For detailed specifications, samples, or customization services related to Carbon Brush for DC Motor, you can reach out directly to Ningbo Haishu Nide International Co., Ltd. Our technical team provides professional support and product recommendations tailored to your application needs.